1. High speed inkjet scanning visual line drawing system for shoe upper

Release time:2024-07-04

Number of views:0

The most concerning issue for enterprises is how to improve production efficiency and product quality? And how to reduce enterprise costs? Especially in the manufacturing industry, the "process", "labor", and "cost" play a crucial role in the input-output ratio relationship. Currently, the shoe upper drawing process has gradually shifted from traditional manual drawing to intelligent fully automatic machine drawing, striving to help enterprises solve the most concerned problems in one go.

Every excellent product has gone through a difficult process of updating and upgrading. Thank you to those factories that have given us the opportunity, the companies that have made our product research and development more and more courageous. Traditional jet valve line drawing equipment has been found to bring far less benefits than predicted in practical applications. The line drawing efficiency may not even be comparable to that of skilled workers, making it even more challenging to face slightly complex lines on the shoe surface.

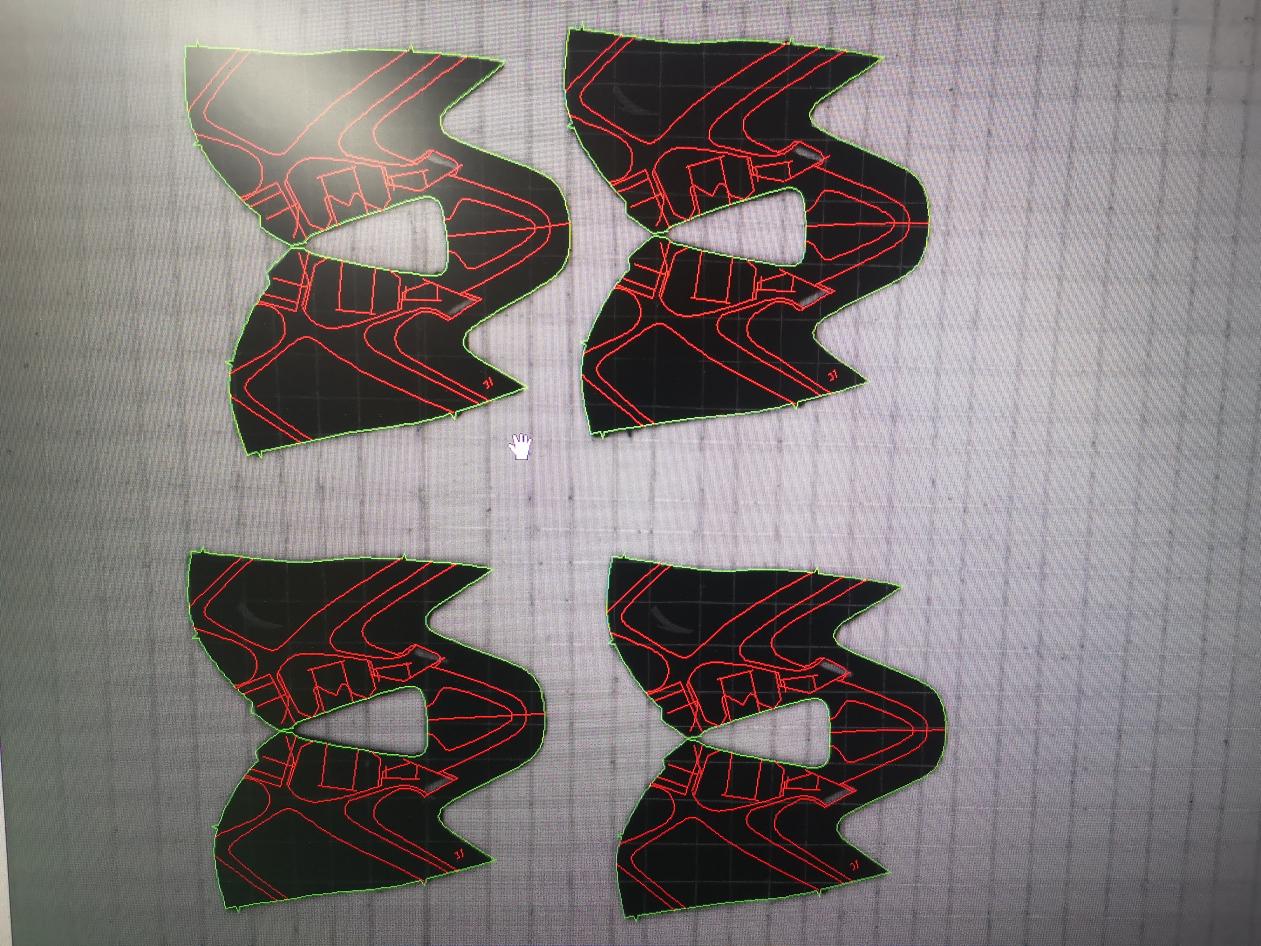

In the process of continuous research and innovation, we have upgraded from traditional jet valve trajectory motion to high-speed scanning spray painting motion, perfectly solving the problem of complex shoe upper lines, and our work efficiency is about 2-3 times that of jet valve trajectory motion.

The problems with traditional shoe upper stitching technology:

1. Low work efficiency and high manual labor intensity

2. Occupying a large number of personnel and high labor costs

3. After the shape of the shoe sample is changed, it becomes a template and is scrapped, resulting in high consumables and a heavy burden on the business operation of the enterprise

4. Making printing plates requires a large amount of wood consumption and takes up space

5. The production of printing plates involves a combination of wood and mesh, requiring plate making machinery and professional technical personnel

6. The workload of watermarks is large, making it difficult to recruit workers

7. The watermark on the screen is prone to clogging due to dry water-based ink, which can cause frequent cleaning of the screen

8. The cleaning of online platforms consumes a large amount of water, resulting in pollution of water resources

9. The watermark line work on a large area of substrate requires a strong labor force and low efficiency

10. Unable to meet the demand for flexible customization

For this reason, Wuhan Shunchen Technology Co., Ltd. has experienced years of technical research and development and accumulation in the shoe material, clothing, advertising and other industries, and has R&D personnel in the technical field. Currently, it has successfully developed and applied a complete set of shoe upper specific fully automatic visual line drawing systems, as well as a matching high-speed inkjet scanning system for automatic shoe upper line drawing.

Advantages of the shoe upper visual line drawing system:

1. Cost reduction: The shoe upper visual line drawing system is equipped with a high-speed scanning inkjet box, which can reduce 4-8 manual line drawing workers per device

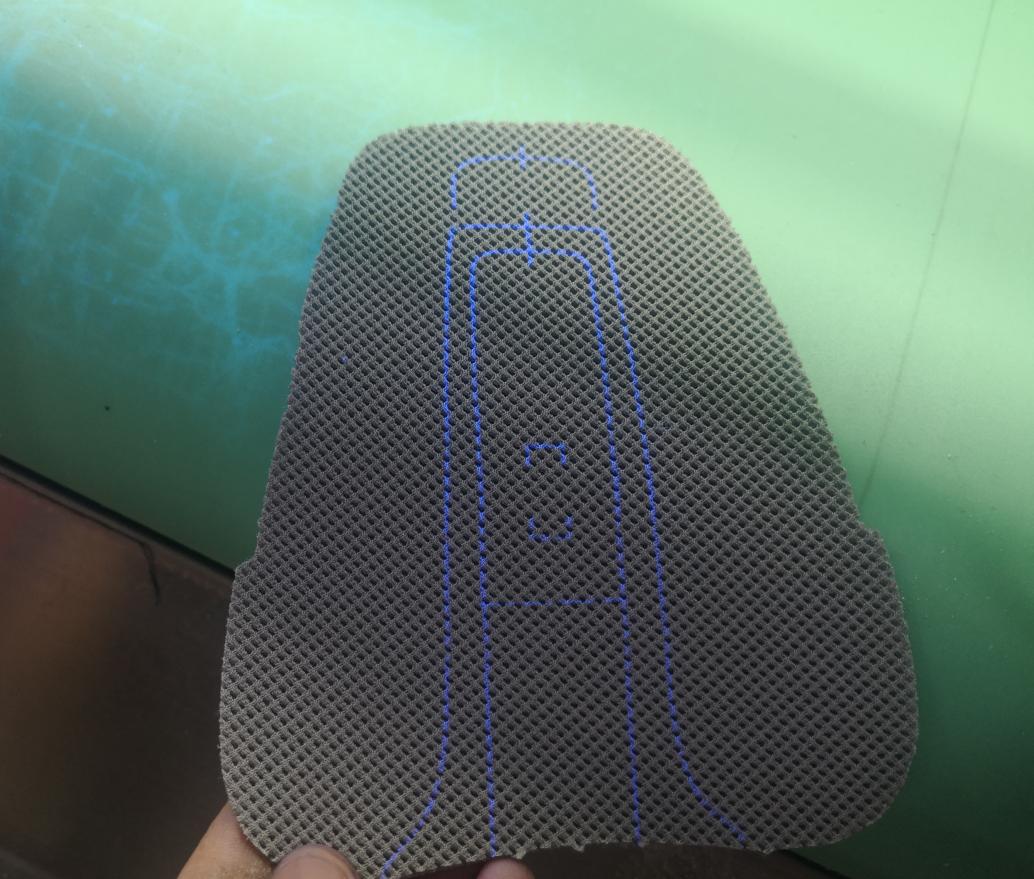

2. High precision: The repeated drawing accuracy is high, with a drawing error as small as ± 0.1mm, and the overall drawing accuracy is as high as 99%

3. Easy to operate: The system operation is simple, and the corresponding template can be directly imported, making it easy for ordinary operators to operate

4. High efficiency: The fully automatic animation line machine is 3-5 times faster than the screen printing line speed and 5-8 times faster than the manual drawing line speed

5. Qualification rate: Equipped with a visual stitching system on the shoe upper, the automation qualification rate is ≥ 99%, and the manual stitching rate is ≤ 90%

6. Low consumables: The high-speed inkjet scanning nozzle has low cost, is easy to replace, and has a small ink output that can be accurately adjusted to save ink

High speed inkjet scanning line drawing system configuration and system functions for shoe uppers:

1. Line drawing accuracy: The format accuracy of 1200mm * 1000mm is ± 0.1mm

2. Standard camera: 20 million pixel high-performance industrial camera, paired with dedicated gigabit network card

3. Template import: supports various DXF, AI, and PLT file formats

4. Deformation matching function: It can automatically recognize the contour of the cut piece according to its different deformation amounts, and the template will deform with the deformation of the cut piece

5. Second level recognition, matching, significantly improving time compared to traditional visual matching

6. High speed scanning motion, with a full page drawing time of within 20 seconds

7. Meet the matching of multiple thicknesses of shoe uppers, with both left and right shoe uppers matching simultaneously

Wuhan Shunchen Technology Co., Ltd.'s shoe upper specific visual line drawing system is an automated intelligent system with core advantages such as fast speed, high accuracy, and strong stability. It perfectly solves a series of problems for shoe factories, such as difficult recruitment, low efficiency, and screen pollution. Whether in terms of system performance, quality, automation, intelligence, and efficiency, it meets the needs of customers.