3. Lace and lace large visual positioning recognition system

Release time:2024-07-04

Number of views:0

Industry pioneering, patented technology

Solving the Difficulties of Lace Craft

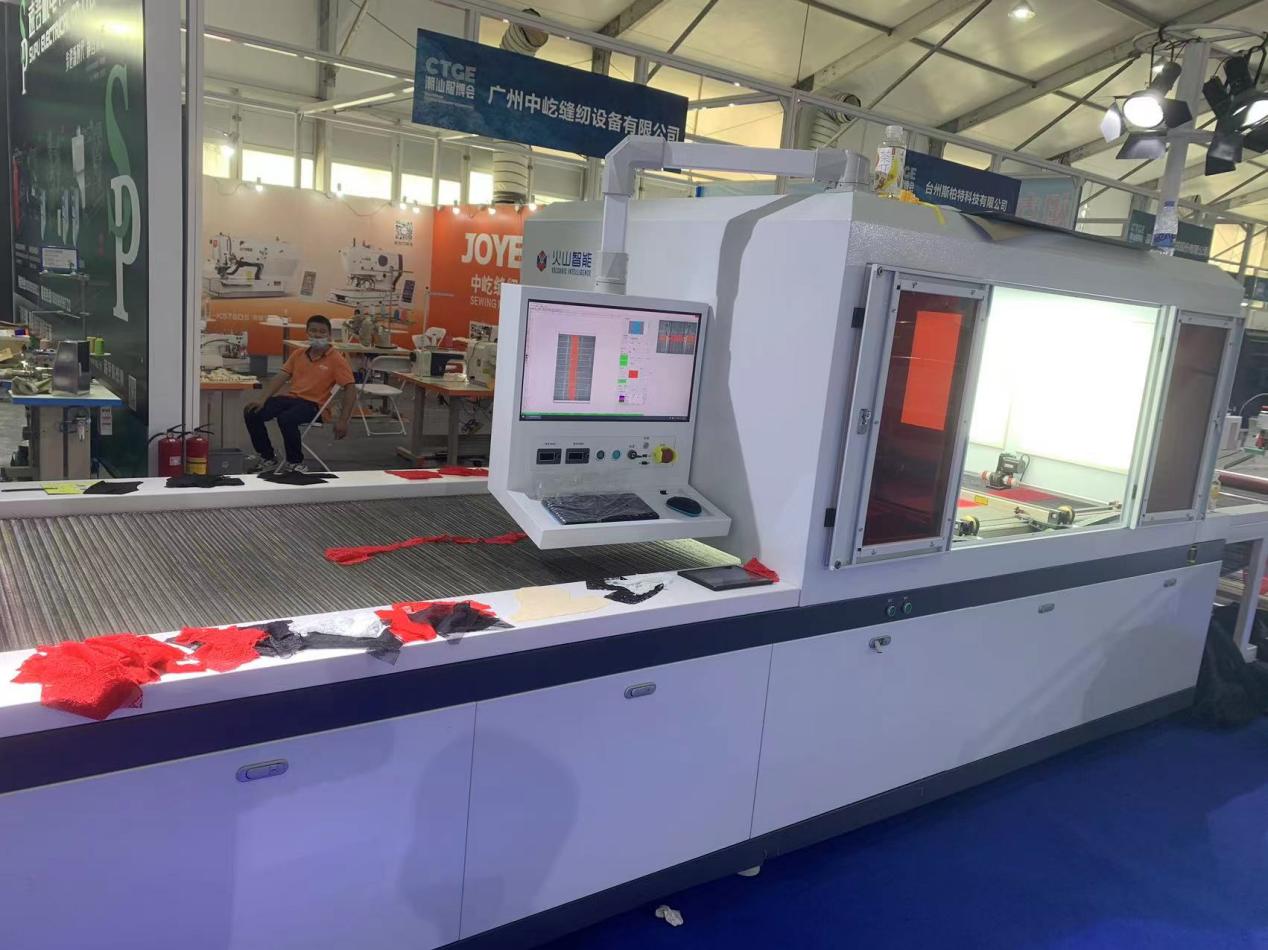

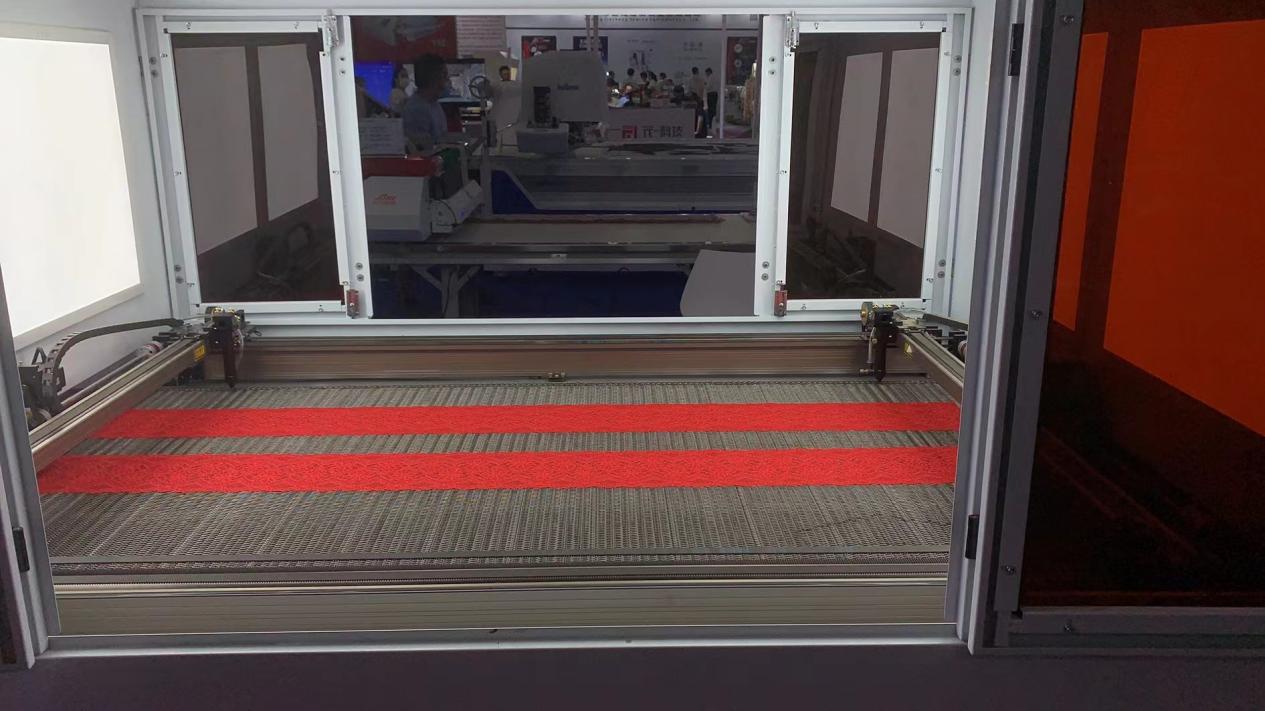

The lace lace lace large visual positioning recognition system for the series of products is independently developed by Wuhan Shunchen Technology Co., Ltd. The product can be applied to lace underwear and lace

The automatic positioning and cutting of lace fabrics such as silk lace and knitted gauze, with continuous multi template high-precision positioning and cutting of wave to flower patterns.

The whole machine is equipped with a panoramic camera positioning system, which can achieve a fully automatic cutting mode of double automatic feeding, automatic photo recognition, and automatic positioning of lace fabric. The equipment adopts a dual independent motion system cutting mode, combined with Shenzhen Qiancheng motion control board and servo motor system, supporting two laser heads to simultaneously cut symmetrical patterns of double lace. The processing path of the two laser heads is reasonably allocated, greatly improving production efficiency and effectively reducing production costs.

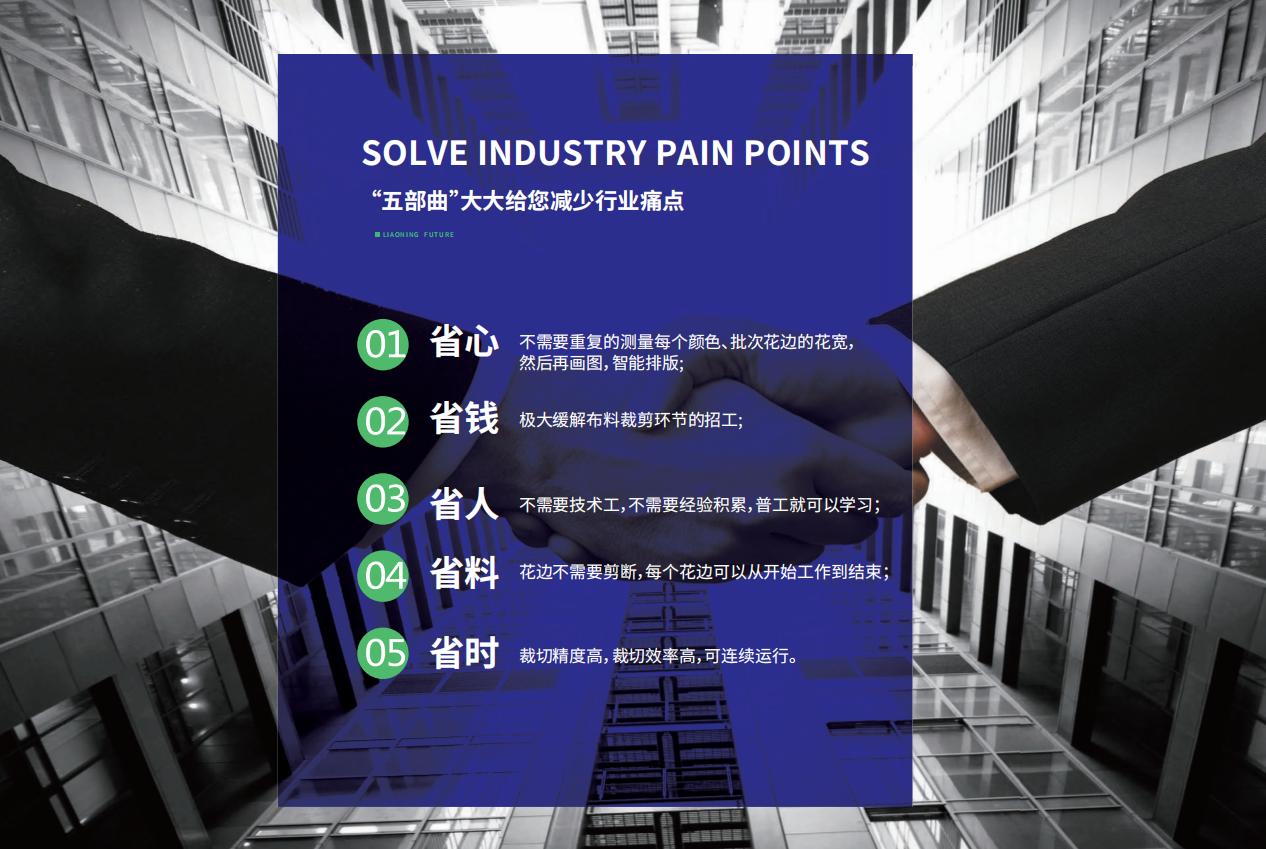

Our strengths:

Processing advantages

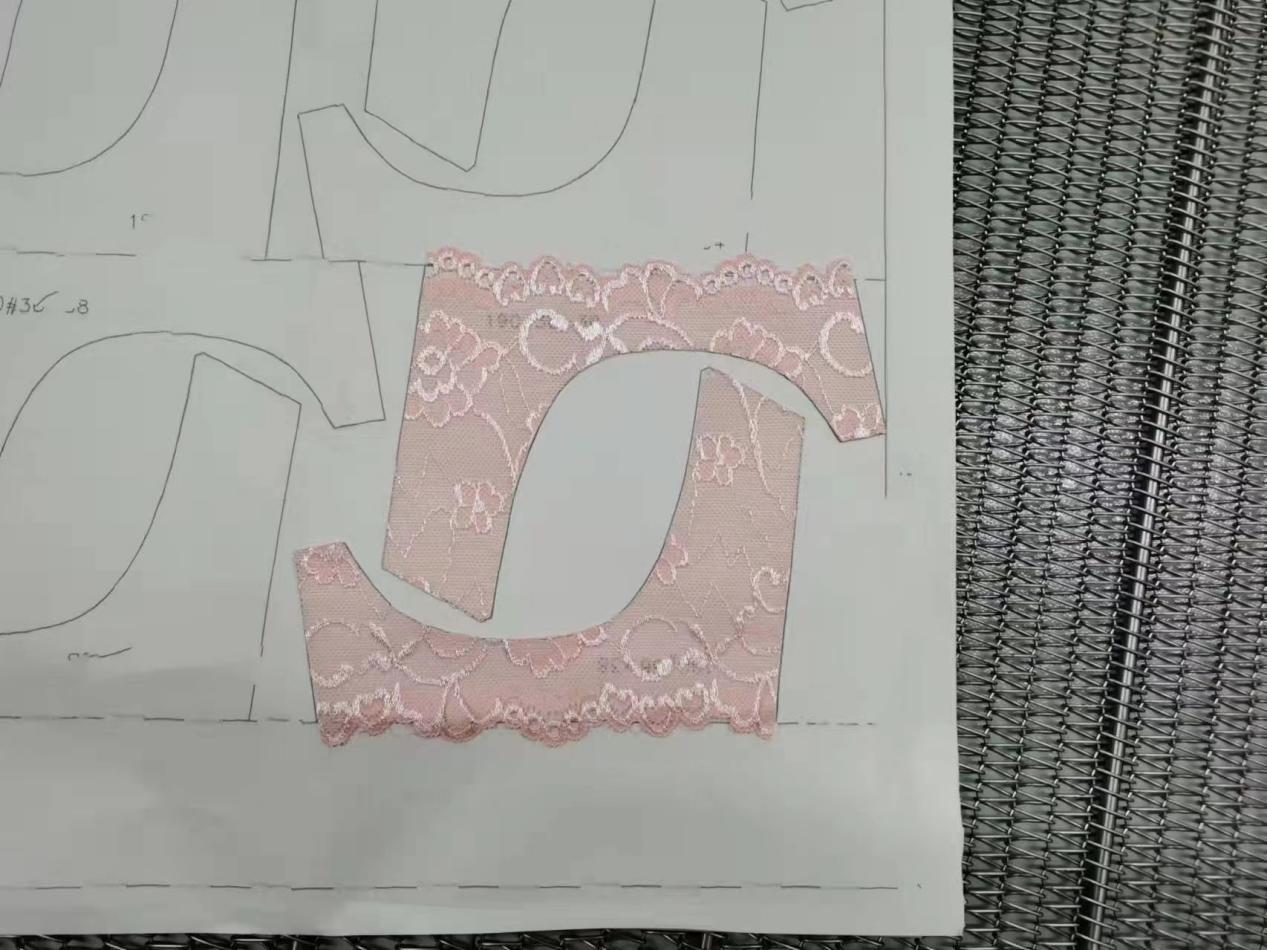

High precision positioning and cutting of waves and flowers;

Non contact cutting, accurate cutting size;

Can cut any shape; Automatic edge locking and anti wire detachment during hot cutting; Smooth and clean edges with no yellow edges;

Fully automatic cyclic feeding, identification, and cutting operations;

The software operation is simple and easy to learn, and requires low proficiency from the operator;

Support simultaneous recognition of multiple lace threads;

Support single chip and combination layout methods;

Supports mixed code typesetting, making it more material efficient.

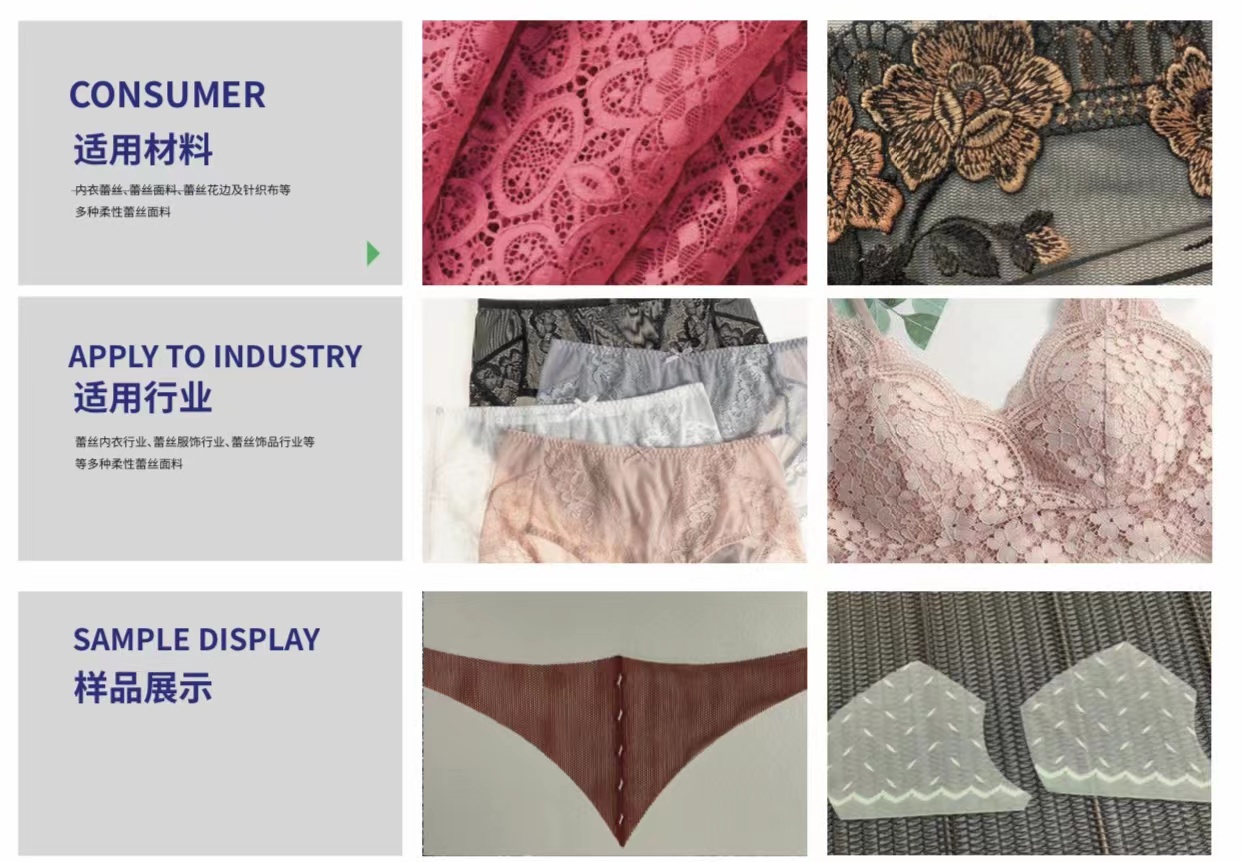

Applicable industries:

Locking edge fabric:

Software intelligent layout, no need to leave a cutting edge in advance, more material efficient than manual layout

No need to lay lace, solving the problem of some materials being laid with lace, which cannot be laid in multiple layers due to slippery materials

Single layer double head cutting ensures production efficiency while solving the problem of uneven width and size of lace caused by shaping. No template is needed, and the drawing file can be imported for direct production, supporting multiple layout methods

To wave to flower:

Supports full-color lace matching, wave positioning, black does not require paper laying

Accurate positioning solves the problem of lace shaping, resulting in uneven spacing and symmetrical matching of parts.

Direct tone traditional craftsmanship involves manual lace arrangement, threading, and cutting processes, saving factory costs and solving recruitment difficulties

No need for a large venue, single person operation, no need for arranging or wearing, incoming goods can be produced at any time

Next article

4. UV visual positioning system